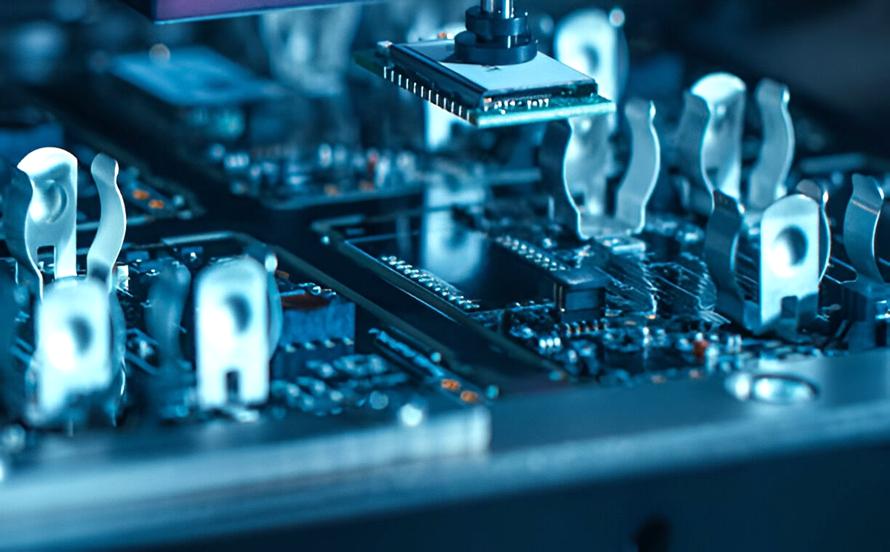

Products made in China are everywhere, maybe in textile, packaging, electronics, food and clothing. China has gained dominance over the world’s consumer products through its abundant business ecosystem. The emergence of wireless 5G technology, widespread automation and the increasing significance of the Internet of Things (IoT) has pushed more manufacturing businesses such as printed circuit board fabrication and assembly, and electronics assembly.

Manufacturing is heavily concentrated in the Asia-Pacific region and China PCB assembly suppliers are recognized as leaders in providing reliable PCBA services. China has taken a huge part of the world’s electronics production, a whopping 36% share of mass production— from computers, smartphones, laptops and cloud servers. We will discuss the popularity of PCB assembly and why it is a top choice for customers.

What are the Different PCBA Technologies?

Before we jump right into understanding the various advantages of PCB assembly services, let’s have a brief overview of printed circuit board assembly techniques.

There are two broad categorizations of PCBA technologies. The first categorization is based on the method by which components are assembled into the PCB and the second is based on the number of sides with components.

- According to Assembly Methods. The two major assembly methods are through “insertion” and “mounting” of the parts on the PCB. The insertion method is known as Through Hole Technology of THT. It is done by inserting the component leads into the holes of the printed circuit boards. Wave soldering is the process by which the components are soldered into the PCB.

The second method is known as Surface Mount Technology or SMT which is done through reflow soldering of mounted parts with solder paste. SMT enables higher-density PCBs compared with THT. There is a third assembly technique known as Mixed Assemblies utilize both SMT and THT to populate the components on the PCB.

- According to the Number of Sides with Components. Single-sided and double-sided assembly methods are the two major categories according to the number of sides with components. Single-sided assembly is the simplest and least costly.

Double-sided assembly, on the other hand, is more expensive since the PCB needs to go through SMT processes twice. This also means that inspection should be done on both sides prolonging the processing times in SMT. The solder paste volume that needs to be used is also higher due to the number of components that need to be mounted.

Advantages of PCB Assembly

Despite efforts to shift production outside China, it is still undeniable that the PCB assembly services still lead among other alternatives due to the following significant advantages.

- Competitive Pricing. PCB assembly services are superior in terms of price offer competitiveness. With their robust production, convenient access to raw material suppliers and seamless logistics provider, PCB assembly suppliers have the competitive edge to offer cheap prices. Labor costs and taxes are also relatively lower in China than other countries which pulls in more investors. Bulk production also enables PCB manufacturers to cut down costs. Another primary reason for cheaper costs is the competitive PCB market in China to attract more customers.

- Quality Control. PCB assembly services maintain best practices to ensure quality control in the production line. Quality control is implemented by complying with international standards, conducting audits, setting up process controls and reinforcing continuous improvement programs. Prioritizing quality is important in China production to ensure consistent and compliant products for both small- and large-scale operations. PCB assembly is a top choice for customers since quality is one of its key strengths despite having low-cost solutions.

- Short Lead Time. Alongside the low cost of PCB assembly services, short lead time is also among the defining factors that make them a top choice. Not only do they have very efficient production processes, but their logistics flow is also as seamless. Automation and digitalization are well-integrated into their logistics services resulting in very fast deliveries. China’s logistics capabilities speed up shipment with their extensive maritime infrastructures and air freight capacities.

- Technical Know-How. As a manufacturing hub, China has developed a skilled workforce and sufficient engineering expertise. Many companies can offer a one-stop solution, from design to PCB fabrication and assembly until box-build. This business strategy further reinforces the technical capabilities of PCB assembly companies. The technical know-how comes with the years of experience also of the manufacturer. The China government is also very supportive of investing in research and development thus the advanced infrastructure for electronics production. China PCB assembly services have vast capabilities such as single- and double-sided PCBs, HDI and flexible PCBs.

- Advanced Manufacturing Capabilities. Installed SMT line capacity in China has tremendously grown over the past years with almost 50% share worldwide. These SMT lines range from simple to advanced assembly lines that are capable of multiple nozzle heads, mixed PCB assemblies and integrated chip shooters. Industrial automation in PCB assembly services has increased to reduce dependence on manual labor which improved their production efficiency. The advanced manufacturing capabilities also improved the quality of assembled PCB products enhancing global competitiveness.

- Sufficient Capacity for Global Demand. The rapid growth of production has boosted the capacity of PCB assembly services to support global demand. PCB companies allow customization to respond to complex requirements for both small and large-scale demand. The significant increase in demand for Electric Vehicles (EVs) worldwide has also made China the biggest automotive supplier of electronics.

- Government Support and Policies. SMT PCB assembly is a top choice for customers because of several combined factors that are even further magnified due to positive government support and policies. Foreign investors are more likely to choose China PCB assembly services due to its convenient business undertaking and low cost. The government also pushes for domestic production to decrease dependence on imported electronics. Intellectual property rights execution has also intensified to shield innovations from theft, empowering the PCB industry. This is done through a patent system of ideas and technologies.

- Sustainability and Environmental Awareness. The drive towards reducing carbon emissions is also reflected in PCB assembly companies. To align with the goal to reach carbon neutrality by 2060, certain materials used in PCB production must be categorized as “green” and non-hazardous to the environment and human health. Other practices also include adopting assembly technologies that will save energy and utilize renewable energy sources. Future business plans are also geared towards compliance with sustainability by identifying carbon emission sources and establishing strategies to reduce pollution. Having sustainability programs also makes China PCB assembly services more attractive to customers, thereby increasing company revenues.