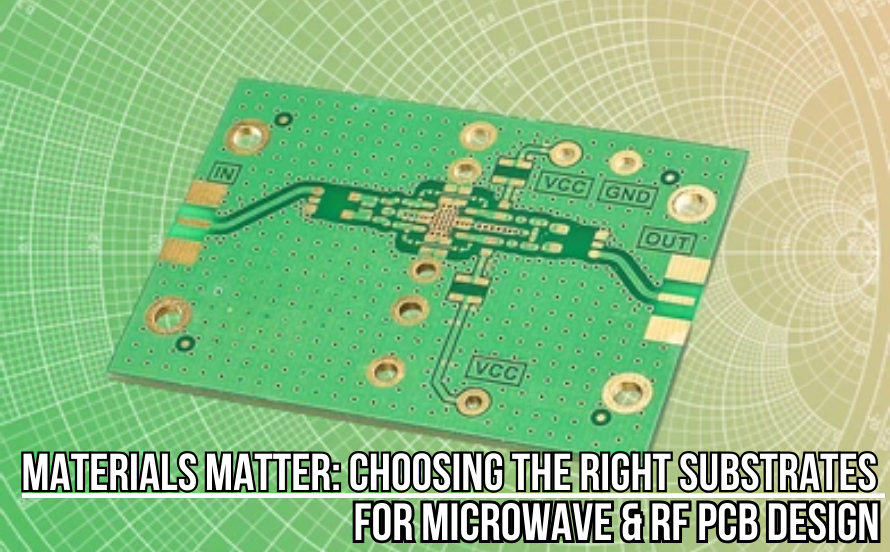

Microwave electronics and their PCBs are a unique bunch of gadgets and components as they operate in signal frequencies ranging from low megahertz to very high gigahertz; which is the microwave frequency range. These products are built differently compared to their traditional counterparts since they require specific materials to work optimally or otherwise, they’ll malfunction once in use.

With that said, in this article – we’ll explore how you can choose the right substrates for Microwave & RF PCB designs to ensure that they’ll work as planned and to avoid any design issues along the way.

What are Microwave & RF PCBs?

To begin our discussion, what is a Microwave & RF PCB? The best way to define what is a Microwave and RF-printed circuit board is that they are special PCBs that contain components that allow them to carry RF or microwave signals. The frequencies that they can carry can range from around 50 megahertz to more than a couple of gigahertz. The frequencies that they can carry and handle will define the variations in the components that they will use in comparison to traditional PCBs.

Unlike traditional PCBs, a microwave & RF PCB uses laminates that are specialized in either electrical, thermal, or mechanical properties that could contribute to its reliability in handling and managing microwave signals. Therefore, microwave PCBs have stricter requirements in manufacturing to ensure that the circuit boards can handle the waves or signals.

Selecting the Right Substrates for Microwave & RF PCB Designs

With the introduction to Microwave & RF PCBs out of the way, let’s move on to our main discussion – finding the ideal substrates. As stated earlier, selecting the materials required for Microwave or RF-printed circuit boards tends to be stricter than traditional PCBs. That’s because the materials and components used in these PCBs must be capable of carrying and withstanding the signal frequencies they are exposed to.

With that said, here are the factors you’ll need to consider in selecting substrates for Microwave and RF PCB designs.

1. The Material’s Loss Tangent Factor

The first factor you’ll need to consider in selecting an ideal Microwave and RF PCB substrate is the material’s loss tangent factor. Loss tangent is a measurement of the electromagnetic energy that’s absorbed into the material which is then released as heat. In other words, it is the measurement of the substrate material’s signal loss.

For example – if you’re aiming to use a microwave PCB in high-power or high-performance settings, ideally you would want to settle for substrate materials with low loss tangent scores as they lessen signal losses in the transmission lines.

2. The Substrate’s Dielectric Constant

The next factor you’ll have to consider is the substrate’s dielectric constant or Dk, which is a measurement that tells us how well the substrate can support an electric field within it. Dielectric constant plays a valuable role in microwave electronics, influencing impedance control and signal integrity.

Ideally, you should settle with substrates with lower Dk to lessen signal loss during transmission, and to speed up signal transmission speeds.

3. Roughness of the Copper Foil

To manufacture the best-performing Microwave and RF PCB, you should ensure the copper foil is smooth as much as possible. The roughness of the copper foil can influence signal losses due to its skin effect. Therefore, if you want to maximize signal performance; settle for smooth copper foils as they are more applicable in high-frequency setups.

4. Environmental Stability Against the Elements

The ideal Microwave and RF PCB substrate must be resistant to element exposure. For the best results – you’d want to use a substrate with low moisture absorption and stable electric properties. These two properties must be compatible with a vast temperature and humidity range to ensure that the PCB is “weatherproofed”.

Utilizing a weatherproofed substrate means that your microwave PCB can operate at consistent performance regardless of weather and moisture levels.

5. Ideal Thermal and Mechanical Properties

Two of the key factors that can help you determine the right substrate for use in a microwave and RF PCB design are to measure their thermal and mechanical properties. The right substrate must be capable of withstanding and functioning even in high-heat environments and mechanical stress.

A good example of a material with mechanical durability and thermal stability is PTFE. which is considered one of the best materials to use for microwave and RF PCBs.

Advantages of Selecting the Right Substrate Material

Before we conclude our discussion, let’s discover why it is important to consider the criteria in selecting the substrate material for Microwave PCBs. In this section, we’ll discover the perks that you will reap from utilizing the ideal substrate materials for this type of printed circuit board. Here are some of the advantages that you will be able to make use of:

1. Consistent Signal Integrity, Optimal Device Performance

By selecting the right substrate material for your Microwave and RF PCBs, you are likely to have circuit boards that can provide consistent signal quality. In turn, because of the consistent signal integrity – expect electronic devices that contain microwave PCBs to function at their best performance.

2. Better Heat Management

In high-frequency setups, heat gets generated a lot which calls for a microwave PCB that has the appropriate thermal properties and dielectric constant. Securing the right substrate for this type of PCB can influence heat dissipation – which means, the device where the microwave PCB is integrated into becomes capable of managing heat better and prevents damage by overheating.

3. Frequency Range Adaptability

Selecting the right substrate for your Microwave and RF PCB ensures that it will adapt easily to its assigned signal frequency ranges. As a result, the device that contains the microwave PCB can carry and emit signals that will not drop in quality or become distorted during transmission.

Reach Optimal Performances with the Right PCB Substrate

To summarize what we’ve covered, the materials required to manufacture a Microwave and RF PCB are more specific to ensure its capability to carry and withstand signal frequencies. Thus, you will need to factor in criteria ranging from the loss tangent to the best thermal and mechanical properties.

By enforcing the criteria for manufacturing this type of PCB – you will be able to create an electronic component that can provide consistent and unimpeded performance.